Munich Urban Colab, Freddie-Mercury-Straße 5, 80797 München

Digitalization Of The Factory

InduSafe AI Software Features

Tracking Preliminary Work Procedures

Tracking Occupational Safety Procedures

Tracking Production Line

Tracking Defect, Non-Defect Products

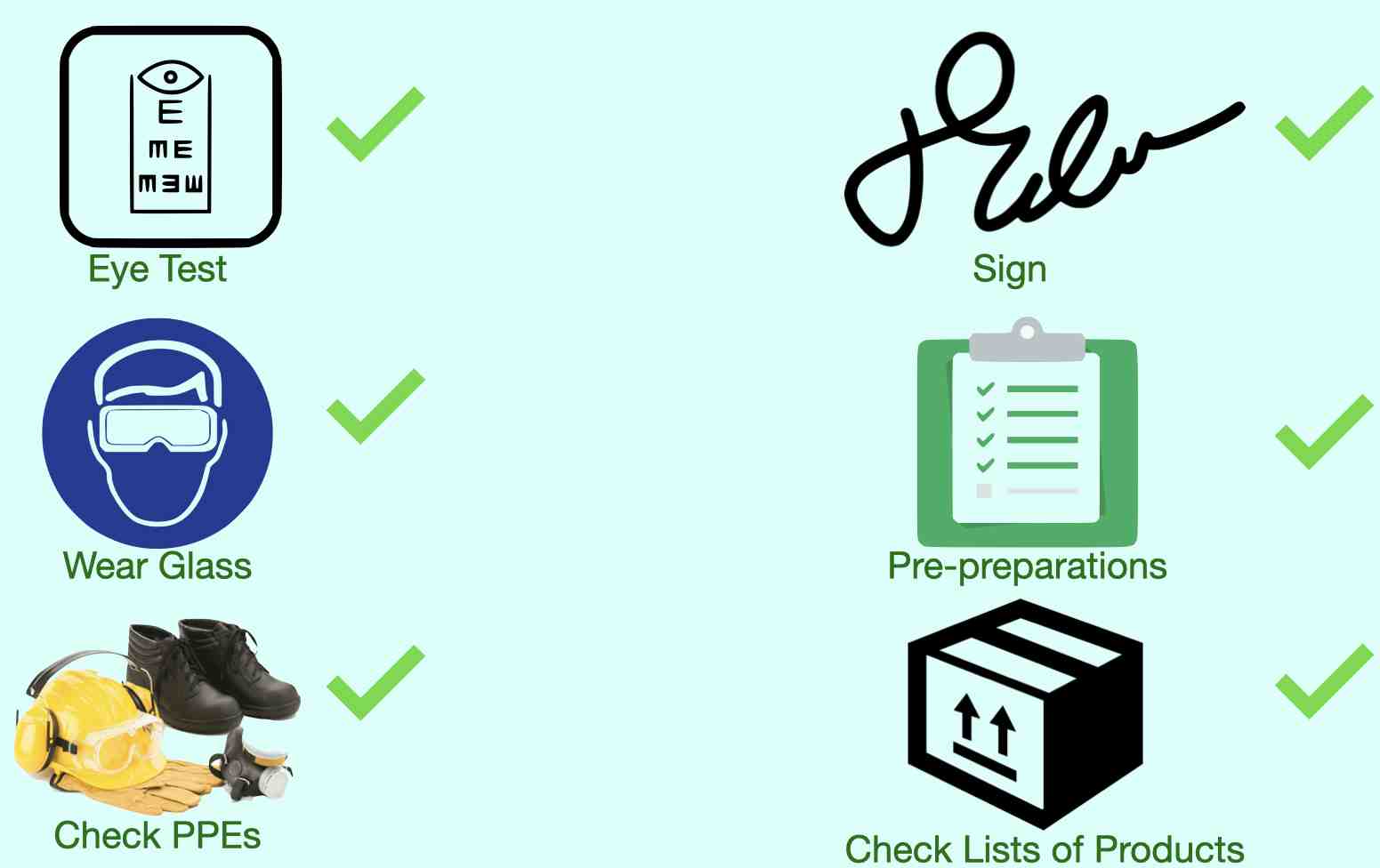

Tracking Preliminary Work Procedures

The procedures that the worker needs to do before starting the work are transferred to the tablet in front of the worker as a check list. The worker checks all the items on the checklist before starting work and starts working.

Tracking Occupational Safety Procedures

A checklist of occupational safety precautions that are necessary for the worker to do the job is displayed to the worker as a checklist. If necessary, real-time alerts can be generated by InduSafe AI if the worker is non-compliant with the occupational safety procedures.

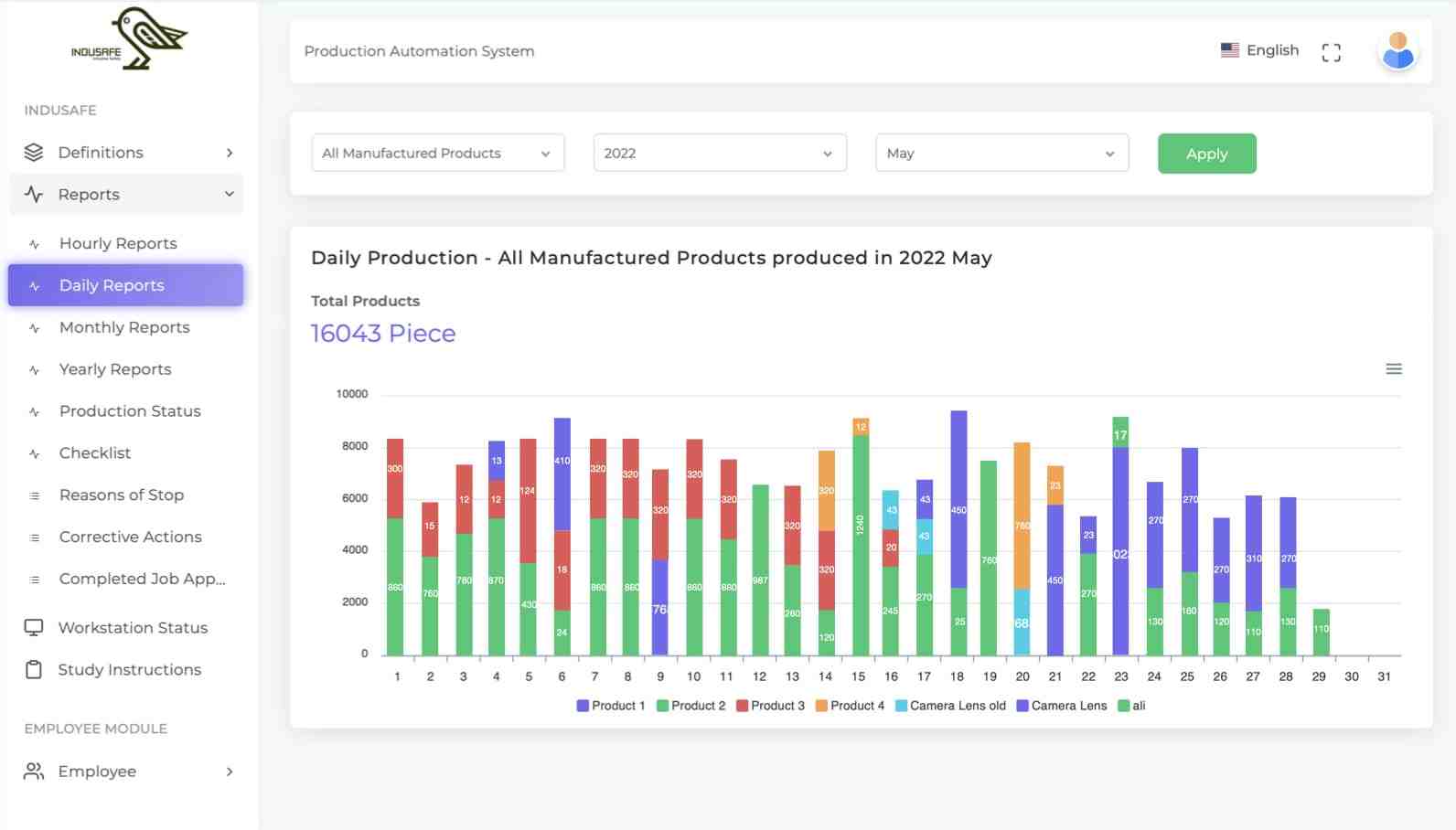

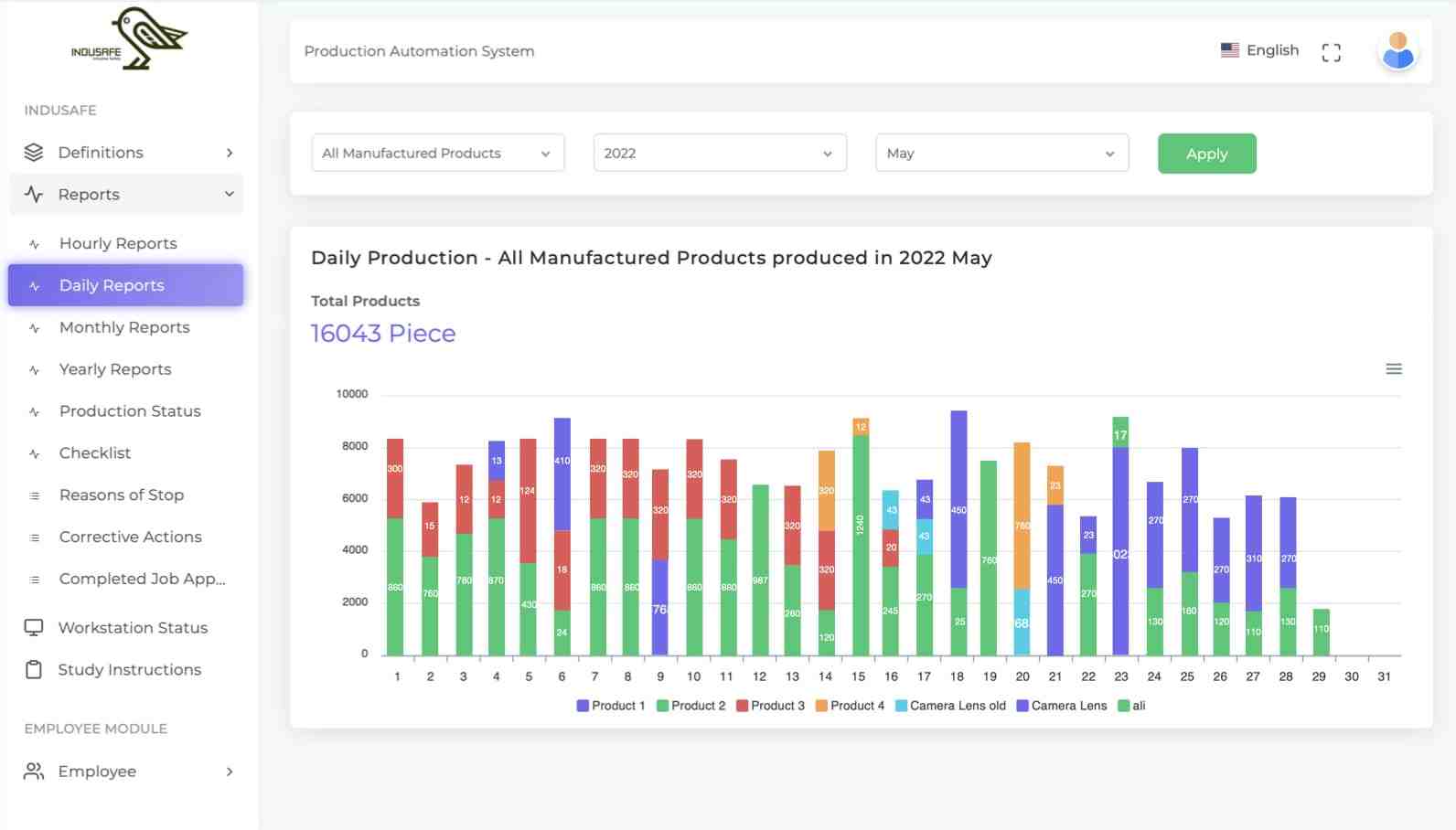

Tracking Production Line

Once the order is created and the order is assigned to a workstation via InduSafe Dashboard, real-time production status can be tracked on InduSafe Dashboard while the worker is performing the work. InduSafe AI can be used to track the number of defect and non-defect products in production line in real-time through the footage taken from the cameras.

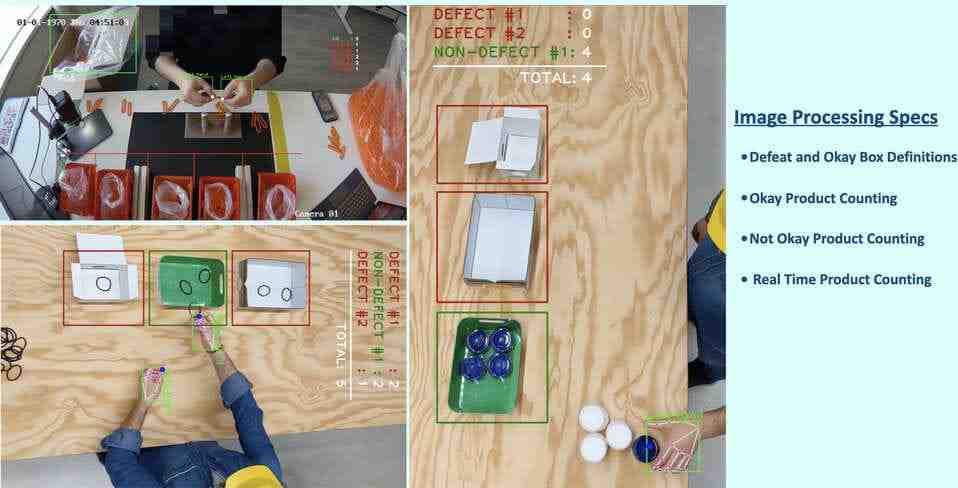

Tracking Defect, Non-Defect Products

High technological and expensive solutions are required to distinguish between Defect and Non-Defect Products in production processes, especially in quality control factories. With the InduSafe AI solutions, counting of Defect, Non-defect products can be performed in real time by processing the footage taken over IP cameras in real time. The products counted with InduSafe AI are transferred to the Dashboard in real time and afterwards, real-time reporting of production is provided.